The RUD Group is a globally certified supplier for defence systems and equipment for land, air and sea. We provide a wide range of innovative material handling and lifting solutions for the defence force that meet and exceed the industry's exacting standards.

RUD Australia engineers and manufactures tailored solutions to industry-specific material handling problems. We help our clients improve productivity and safety while reducing maintenance and operational costs.

Our product range includes more than 700 lifting slings and lashing points for multi-directional loading. Every product gets tested and certified to meet RUD’s exceptional standards for strength, performance and endurance.

A subsidiary of the globally renowned RUD Group, RUD Australia works with clients across Australia and New Zealand. Our in-house engineers and product experts provide technical insights and design innovations to help our clients discover new opportunities for success.

Our 6000m2 manufacturing facility located in Brisbane, QLD has a dedicated in-house team who can offer complete engineered manufacturing solutions. Our qualified team of CPeng/RPEQ engineers and experienced tradespeople can manage every aspect of your project or service requirements to ensure you receive the highest quality RUD solutions.

Our complete range of more than 370 different lifting slings and other products are tested and assessed against our strict quality-control measures to ensure maximum safety for your business.

Our collaborative approach makes us a preferred partner of choice for organisations who value quality and safety.

RUD Germany lifted a gigantic lattice cage in downtown Berlin with a length of 25 meters and weight of around 56 tons, which is the largest and heaviest lattice cage ever erected and sunk into the ground.

RUD Australia supplied the hoops and lifting design for the erection of bridge girders in the Pacific Highway Upgrade Project on Exit 41 which was completed by Universal Cranes (part of the Smithbridge Group) along with Georgiou Group.

RUD has been providing innovative material handling solutions to German wind turbine manufacturer Enercon such as the Tecdos Tool Mover which is used to turn heavy rotor-hubs weighing up to 65 ton.

RUD's lashing solutions recently provided the ability to safely transport 129 rotor blades required for wind turbines being built at the Eneco wind farm project in the Netherlands.

RUD recently solved a pump removal problem for the largest wastewater pump station for Logan City Council, the Alfred Street SPS69 wastewater pump station, situated in south-east QLD Australia, servicing 200,000 people in the Logan local government area.

This project was the final stage of construction required to complete the Townsville Ring Road link, a 22 km freight bypass of Townsville.

Earthworks, drainage, pavement, retaining walls, concrete barriers, signs and finishing works were also part of the project.

While working on the Wheatstone Project, lead project rigging engineer, Dusko Barac, proposed an innovative idea. Dusko realised there was an opportunity to increase the operational envelope of the permanent facility bridge cranes to include maintenance works. The reach of the gantry cranes needed to be extended to allow them to pick up components previously out of reach.

SIMS Metal was constructing a new metal recycling plant in Perth. A high-quality conveyor system was quickly identified as being critical to the plant’s success.

The conveyor system needed to allow a controlled feed to an inclined belt. Metering and controlled flow were also essential features needed in the system.

At Eraring Power Station, a fleet of eight Condensate Extraction Pumps (CEPs) were failing more frequently than expected. With every failure, the CEP was offline for a minimum of eight days while being overhauled. The bearing was first disassembled over three days. Then, the pump was removed in two sections while personnel worked under the suspended load to uncouple the pump.

Australia’s hard rock quarries are among the world’s toughest environments for rubber-tyred machines. The West Burleigh Quarry has provided road base and quality aggregates to the Gold Coast area for many years. Uninterrupted supply is essential for many projects in the area.

At the Jundee Nickel Mine, extreme tyre wear and premature tyre failure had become an ongoing problem. Tyre issues were frequent but unpredictable. Replacement tyres were often difficult to source, leaving trucks and machinery out of service for long periods of time.

Defence forces encounter a range of unique materials handling challenges. While serving in the defence forces has inherent dangers, risk is managed seriously and proactively. Reducing the exposure of troops to unnecessary risk is a priority for defence organisations.

The Australian Defence Force has a range of large and heavy vehicles, like the Bushmaster PMV (Protected Mobility Vehicle), in their fleets. The diversity of the vehicles, as well as the unique operating environment of defence force workshops, required a specialist vehicle lifting system.

We are happy to deal with RUD because of their product quality, customer service and competitive pricing. They are very efficient when submitting quotes with a short lead time and are always available when we need them.

Onsite support is excellent and always professional.

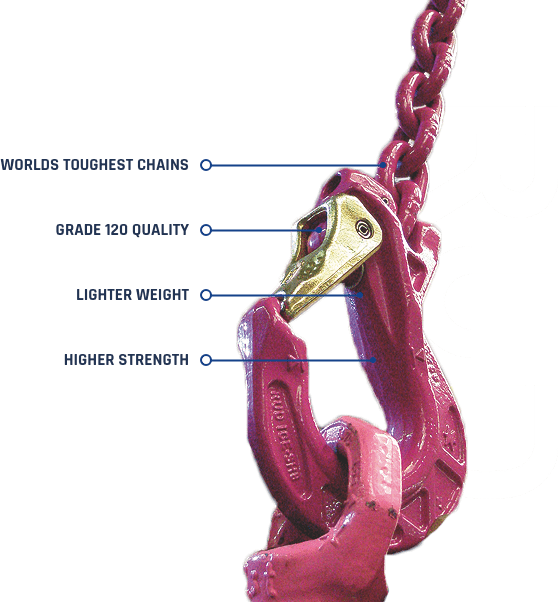

RUD Chains has a great product with an exceptional back-up and field service. We have previously bought from Chinese manufacturers and European companies, but we will stay with RUD due to the quality of the product and availability of service personnel.

Patterson Crane Hire loves a challenge and RUD lifting gear helps us solve these challenges. The weight saving gains when we use their Grade 120 ICE range really makes a difference and minimises our risk when we are managing difficult, heavy lifts.

Simply put, this is why we choose to work with quality suppliers like RUD.

At Holcim (Werribee) we rely on RUD Tyre Protection Chains. Their strong expertise and professionalism is on display when they fit and maintain our chains on site. The team works hard to keep us safe, enable our machines to stay in operation and minimise our costs.

Air & Allied Sales (Pacific) has partnered with RUD Chains for the past 25 years to deliver outstanding engineered solutions. The professional and continued relationship with Ian and his team allows us to continue to support our customers above and beyond their needs.

Our recent requirements have pushed the limits of a standard supplier’s capabilities, but RUD Chains have never...

As Managing Director of ACRAN, we are always excited to provide innovative and quality technical solutions to the market for industrial ventilation, filtration and noise control solutions.

Recently we completed a project where RUD chain drives provided a controlled drive solution for an Engineered lift and fulfilled the requirements. ACRAN is grateful for the technical and on-site...

At Gemilang, we’re confident that our high-quality Endurequip-made Portalifts and vehicle stands will continue to serve us well as we build more buses for the Australian market. These provide us unparalleled underbody access, thereby giving our clients the reassurance that every single bus component, from top to bottom, is designed, manufactured, secured and inspected thoroughly by our...

The team at Jilalan appreciate the quality service you provided in the design, fabrication and commissioning of our platforms for our Wagon remediation project.

RUD's attention to detail and great communications skills ensured that our project was completed to the highest standard and exceeded our expectations. From the start of the procurement process you committed to ensuring time...

Grima Recycling have been working the team at RUD in realising our plant expansion project. The modular RUD chain conveyor has proved to be reliable and effective for the transfer of our recycled products from the loader hopper and up the inclined slop as part of our new process line. The regular contact and support provided by RUD compliments the RUD system quality.

ENCO Precast have been involved with RUD for over 10 years now, predominantly for the supply of the Philipp Group Lifting Hoops for Prestressed Precast Concrete elements for bridges. The engineering support led by RUD's Engineering Manager Matt Pauli is always outstanding and has kept us loyal to RUD.

RUD’s service and product support have been excellent. We are happy to recommend RUD to anyone who has problems with their tyre life.